Sale of

bovine leather

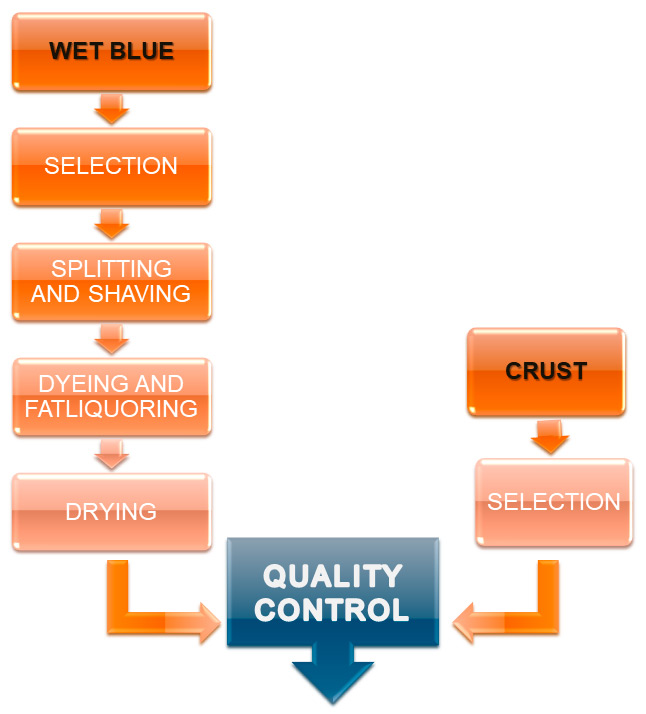

Working process – today

The leather manufacturing process is divided into four fundamental sub-processes:

1. Preservation (Treatment made with salt or pickle in order to protect leather from the degrading influence of the microorganisms).

4. Finishing: (Define the final aspect in order to uniform the colour and makes leather softer and with a natural feel).

Working process at New Pel Company Spa S.R.L.

New Pel Company mainly buys the raw material at two different steps of production: crust or wet-blue, always after a sever selection in the country of origin.

After hides are tanned, they are fed through a machine which cuts the hide into a valuable top grain portion and a split layer. After splitting, the hide is put through another machine, which shaves it to uniform thickness.

The dying process is made with natural dyes and products such as tannins, fats and water, by drumming leather in a rotating drum. After this process leather become soft and with a natural feel

After the dying process leather is wet, therefore they are lay on special nets and put into big ovens for several hours.

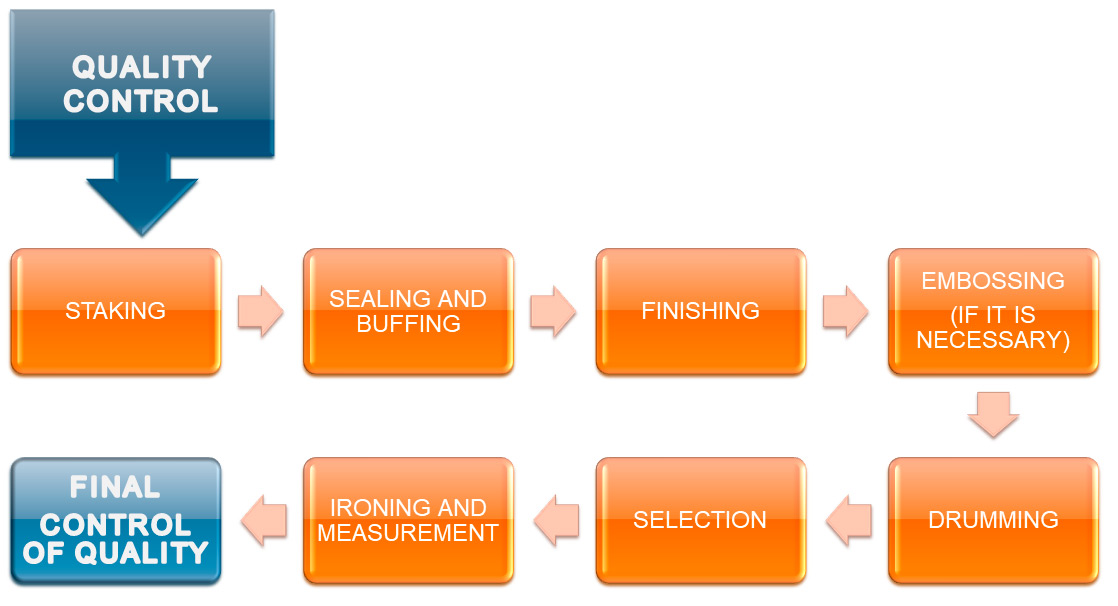

Sealing and buffing

The scars and imperfections are covered by hand with a lotion (Stucco), after than that, the surplus plaster is removed by an abrasive paper.

In order to achieve the final aspect, they spray the colour together with chemical products.

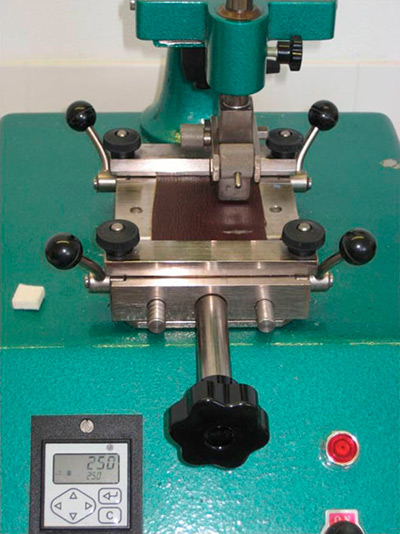

Embossing (if it is necessary)

Leather can be embossed with some patterns by press at high T°C.

Process made by a rotating machine called drum, in which they give out heat in order to make leather softer and with a natural feel.

leather is ironing by a warm roller and at the same time it is measured with an electronic machine.

Final control of quality